Umang Marketing is the authorized distributors for high end Solar Diamond Tools, which includes Diamond Files, Diamond Wheels, Electroplated Wheels, Honing Stones, PCD/CBN Inserts & Special Tools as per Customers' Drawing, Diamond Paste, Single Point Natural Dressers, Standard Diamond Dresser Shank, Throw-away Diamond Dresser Shank, Shapping Tools, Cluster Dressers etc.

We also offer dressing tools for silicon carbide and aluminium oxide wheels, Multipoint Indexable Crown, Hexogonal Disc Diamond Dressers, Multipoint Disc, Diamonr Grit Impregnated Dressers, Blade Dressers, Diamond Indenters etc. Solar Diamond is the Diamond Tools manufacturing company in India.

1. Diamond Dressers

• Single Point • MCD Single Point • CVD Single Point • Grit Dresser • Cluster Dresser • Crown Dresser

• Hex-Disc Dresser • Chisel Dresser • MD-20 Roller • Ball Wheel Dresser • Blade Dresser • MCD Blade Dresser • CVD Blade Dresser • Shaped CVD Blade Dresser • Diamond Guaging Point • Indenter (Natural Diamond & MCD)

2. Honing Stone

Metal Bond Diamond & CBN Stone:

• Standard Stone

• Compact Stone

• Solid Stone

• Slotted Stone

• Stone with Shoe

• Special Stone

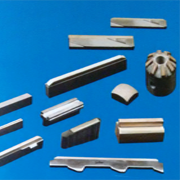

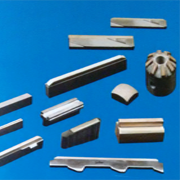

PCD & PCBN Cutting Tools

• ISO Insert

• Brazed Tool

• Special Tool

• Full Top PCD

• Solid PCBN • PCD Dresser

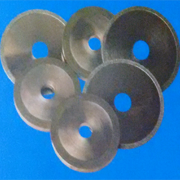

3. Electroplated Products

• Diamond & CBN File

• Diamond CBN ID Grinding Wheel

• Diamond Cut-Off Wheel

• Special Wheel

• Special Shape Tool

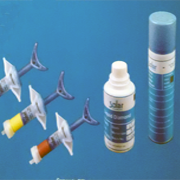

4. Diamond Lapping Products

• Diamond Paste

• Liquid Diamond

• OS Fluid

• Polishing Cloth

• Lapping Oil

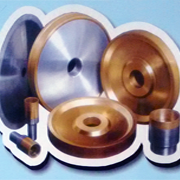

5. Solar Diamond Wheels

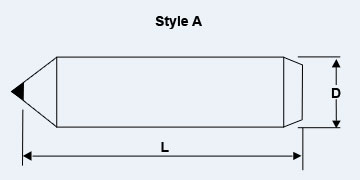

6. Single Point Diamond Dressers - Natural and Bruted Point

Single point "bruted diamond" dressers are made with selected "congo Rounds" mounted in a matrix. A single cutting edge is presented to the grinding wheel.

Diamonds for single point dressers are selected in accordance with quality and size. The question of using a superior, average or commercial quality, depends on the grinding finish required and the machines and working parameters.

We offer three grades namely A, B & C for all the diamond size, Availability: 0.25 Ct to 5.00 Ct

Natural Point Diamonds: The diamond points are naturally formed. (Not man made like grades A, B & C). This is a gift of nature. Natural Point Diamond Dressers have high form retention properties. Availability: 0.10 Ct to 2.50 Ct

Guideline for single-point diamond dressers:

Considerable care should be taken in mounting the diamond dresser in position. Diamonds are sensitive to shock and impact.

The dresser must be clamped rigidly in place to avoid vibration once dressing begins.

An ample supply of coolant should be directed at the diamond point before dressing begins, as the sudden application of coolant to the diamond once it has heated up can cause it to shatter.

The diamond holder should not be set directly on the center of the grinding wheel, but at an angle of 5-15 to the direction of the wheel so that it appears to be "trailing".

At normal wheel peripheral speeds, dressing rates of approximately 20-25 m/sec can be achieved.

The maximum depth of cut achieved per dressing pass is 0.03 mm or on fine grit wheels, approximately 0.005-0.01 mm.

The cross feed rate is dependent upon grit size and can have a marked influence on the quality of the finish imparted to the grinding wheel surface. The lower the feed rate, the finer the surface finish. We would recommend following feed rates per revolution of the grinding wheel.

| FEED RATES PER REVOLUTION |

| Grinding Wheel Grit Size |

Feed Rate in MM/Rev |

| 30-46 |

0.60 - 0.30 |

| 50-120 |

0.30 - 0.10 |

| 180-320 |

0.10 - 0.02 |

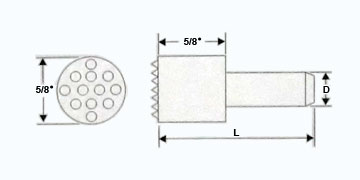

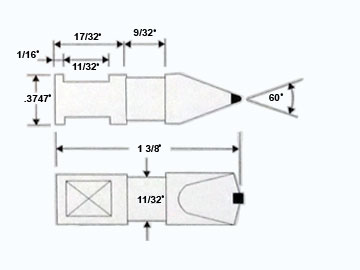

Standards shanks 1/2" x 6" upto 2.50 cts. Standards shanks 5/8" x 6" over 2.50 cts. Shanks are also fabricated according to your blue prints. While ordering specify grade & ct. wt.

| SINGLE POINT DIAMOND DRESSERS |

| CT. SIZE |

GRADE AVAILABLE |

DIMENSIONS |

|

NP A B C |

|

0.25

0.35

0.50

0.75

|

✓ ✓ ✓ ✓

✓ ✓ ✓ ✓

✓ ✓ ✓ ✓

✓ ✓ ✓ ✓

|

|

1.00

1.50

2.00

2.50

3.00

|

✓ ✓ ✓ ✓

✓ ✓ ✓ ✓

✓ ✓ ✓ ✓

✓ ✓ ✓ ✓

✗ ✓ ✓ ✓

|

|

3.50

4.00

4.50

5.00

|

✗ ✓ ✓ ✓

✗ ✓ ✓ ✓

✗ ✓ ✓ ✓

✗ ✓ ✓ ✓

|

|

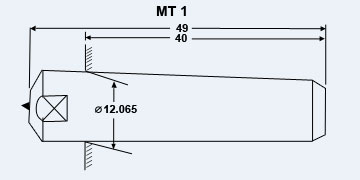

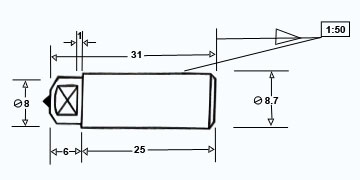

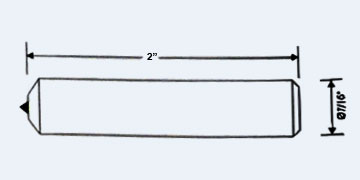

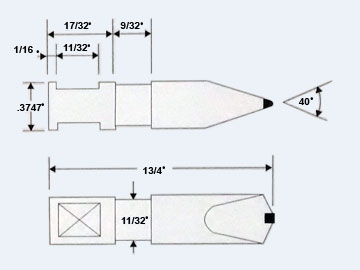

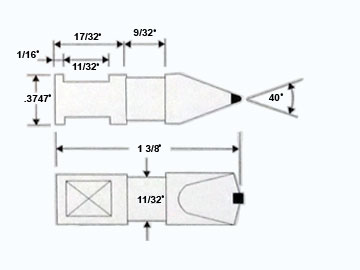

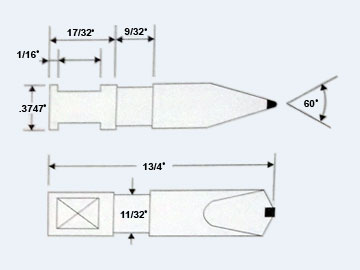

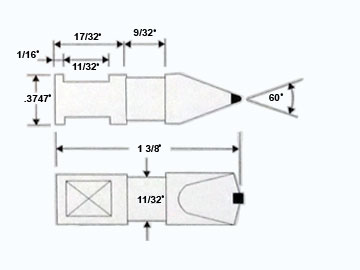

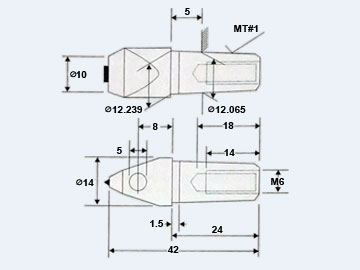

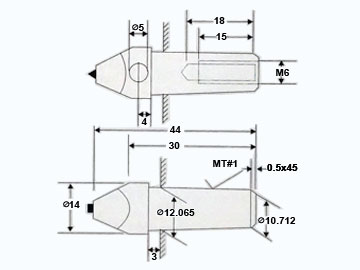

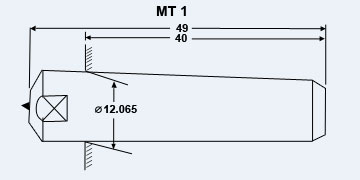

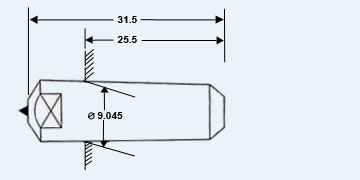

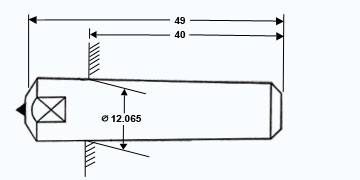

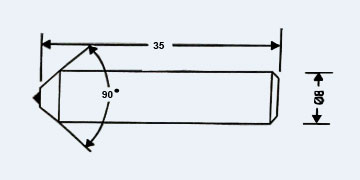

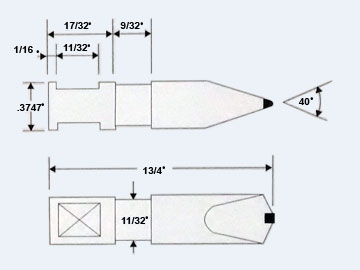

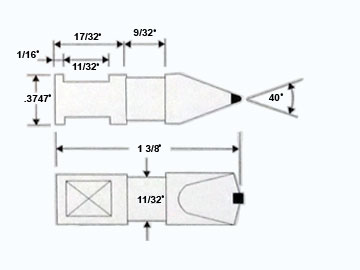

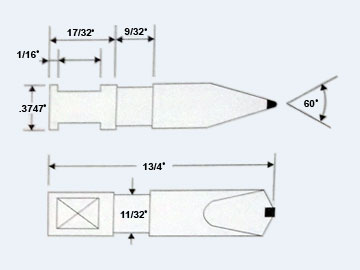

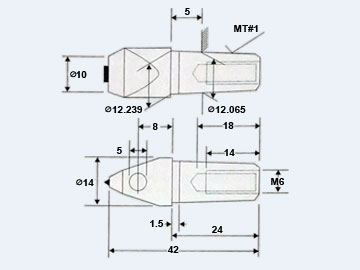

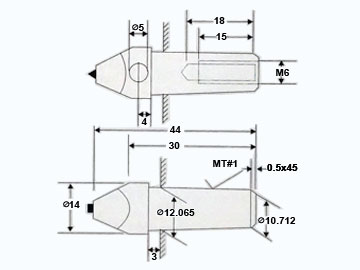

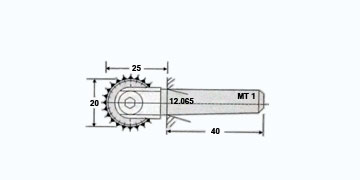

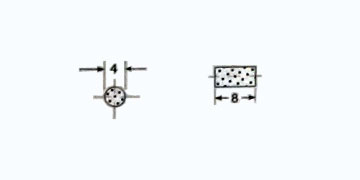

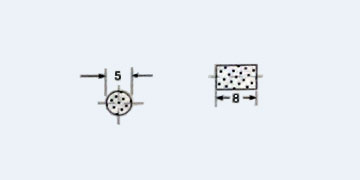

7. Throw-Away Diamond Dressers

Throw-away type diamond dressers are made of small selected crystal shape or octahedral diamonds, mounted in a matrix. Only one cutting edge is presented to the grinding wheel.

Diamonds for throw-away type diamond dressers are selected for their strength, degree of sharpness and lack of detrimental flaws. The proper selection of size and quality appropriate for a given application requires qualified and experienced judgement.

As the name suggests is really a throw - away dresser that means no maintenance, no re-setting of diamond required.

They are used for truing and dressing small and medium sized wheels. For larger wheels with small widths they are used only in profile dressing applications.

These tools are not suited to dress wheels with grit size coarser than 60 mesh.

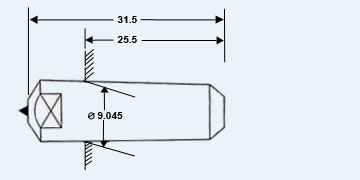

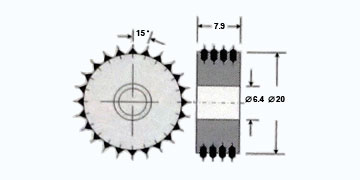

| THROW-AWAY DIAMOND DRESSERS |

| NO. |

SIZE |

CT. WT. |

DIMENSIONS |

1 |

MT-0 |

0.05

0.07

0.10

0.15

0.20

0.25

|

|

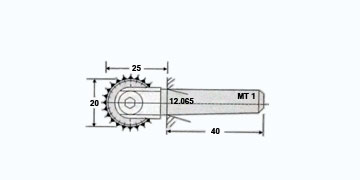

2 |

MT-1 |

0.05

0.07

0.10

0.15

0.20

0.25

|

|

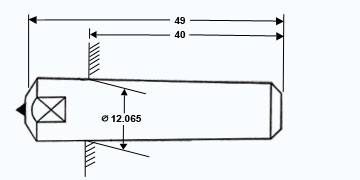

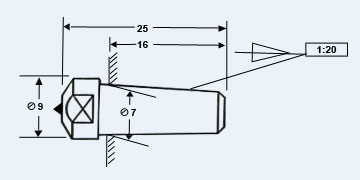

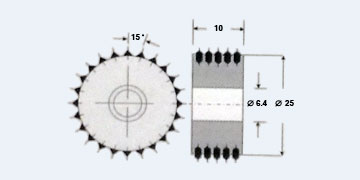

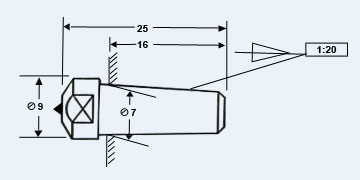

3 |

1:20 Taper |

0.05

0.07

0.10

0.15

0.20

0.25

|

|

| THROW-AWAY DIAMOND DRESSERS |

| NO. |

SIZE |

CT. WT. |

DIMENSIONS |

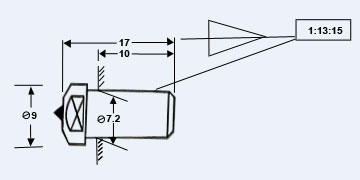

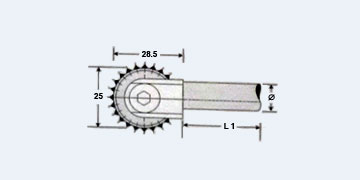

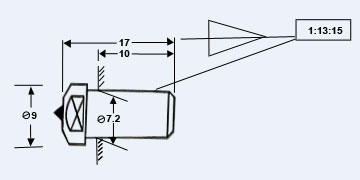

4 |

1:13:15 |

0.05

0.10

0.15

0.20

|

|

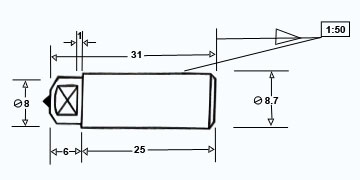

5 |

Vonmard |

0.05

0.08

0.10

0.15

0.20

|

|

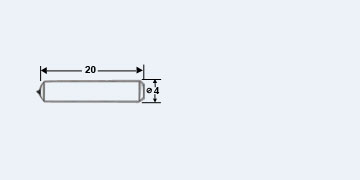

6 |

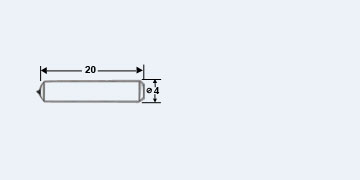

4 x 20 mm |

0.05

0.08

|

|

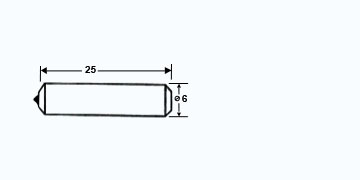

7 |

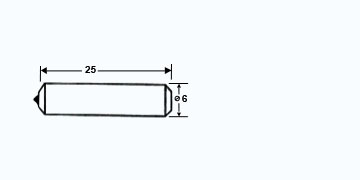

6 x 25 |

0.05

0.08

0.10

|

|

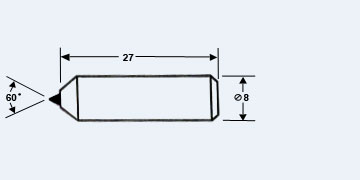

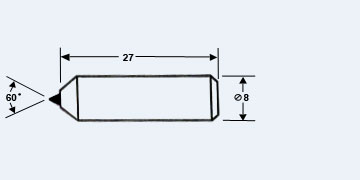

8 |

8 x 27 mm |

0.05

0.10

0.15

0.20

|

|

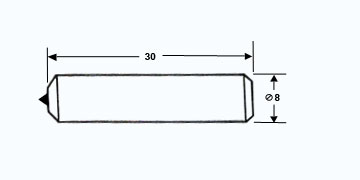

9 |

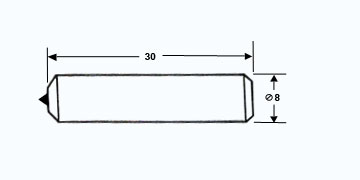

8 x 30 mm |

0.05

0.08

0.10

|

|

| THROW-AWAY DIAMOND DRESSERS |

| NO. |

SIZE |

CT. WT. |

DIMENSIONS |

10 |

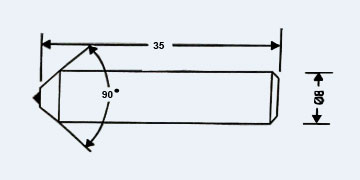

8 x 25 mm |

0.05

0.08

0.10

|

|

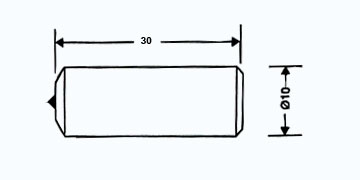

11 |

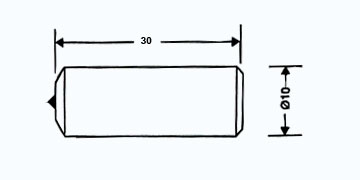

10 x 30 mm |

0.05

0.08

0.10

|

|

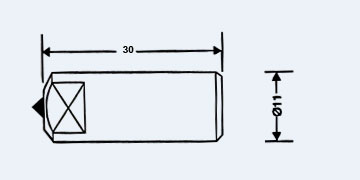

12 |

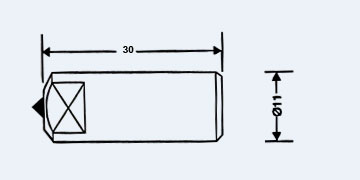

11 x 30 mm |

0.05

0.08

0.10

|

|

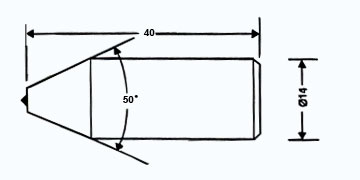

13 |

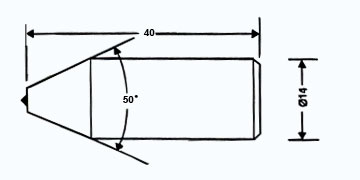

14 x 40 mm |

0.05

0.08

0.10

|

|

14 |

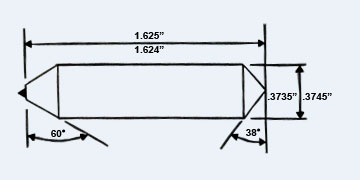

48-4105 |

0.05

|

|

| THROW-AWAY DIAMOND DRESSERS |

| NO. |

SIZE |

CT. WT. |

DIMENSIONS |

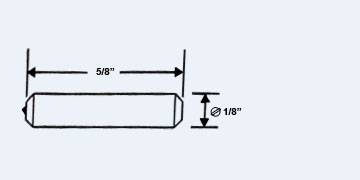

15 |

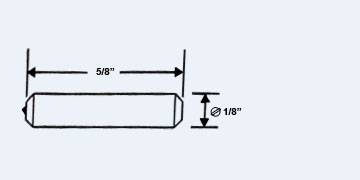

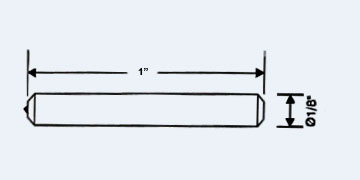

1/8" x 5/8" |

0.03

|

|

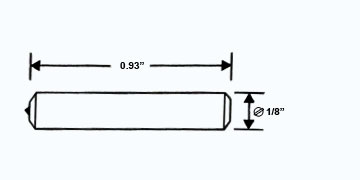

16 |

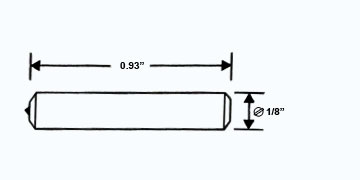

1/8" x 0.93" |

0.03

|

|

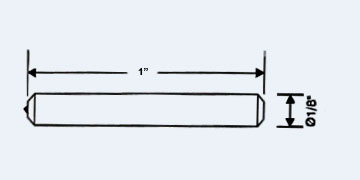

17 |

1/8" x 1" |

0.03

|

|

18 |

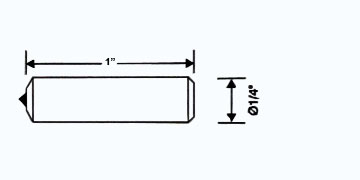

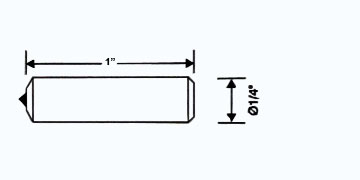

1/4" x 1" |

0.05

|

|

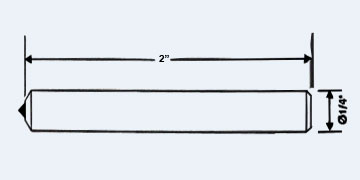

19 |

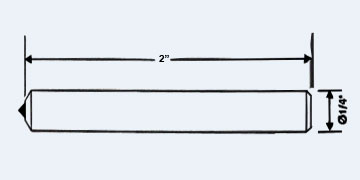

1/4" x 2" |

0.05

|

|

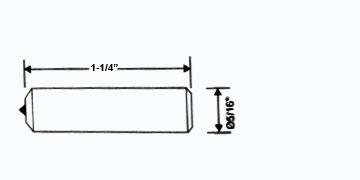

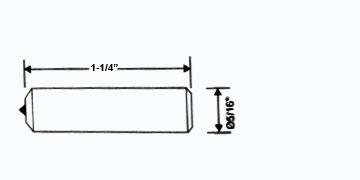

20 |

5/6" x 1-1/4" |

0.05

0.08

0.10

|

|

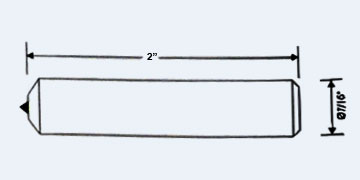

21 |

7/16" x 2" |

0.05

0.08

0.10

|

|

8. Shaping Tools

Profiling and copy dressing pf grinding wheels make high demands on profile retention capability and thus on wear - resistance of the diamond tool.

Wherever diamond blade type tools can not meet these requirements due to the specific grinding wheel geometry, precision ground shaping tools are the solution. Shaping tools feature the unique "structure-cut" to ensure optimum tool life. They are manufactured only from the highest grade of natural diamonds and undergo stringent quality control during manufacturing.

Important Point to Consider:

• Choose a diamond with the largest included angle and toughest geometric shape allowed by the profile requirements

• Use a drag angle, where possible to maximize cutting edge life.

• Make sure that tool is rigidly mounted.

• Follow machine manufacturer's instructions and recommendations.

| SHAPING TOOLS |

| TYPE |

CAT NO. |

RADIUS IN INCHES |

DIMENSIONS |

Diaform |

SF 4125

SF 4250

SF 4500 |

0.250

0.500

|

|

Diaform |

SF 4125

SF 4250

SF 4500 |

0.125

0.250

0.500

|

|

Diaform |

SF 6125

SF 6250

SF 6500 |

0.125

0.250

0.500

|

|

Diaform |

SF 6125

SF 6250

SF 6500 |

0.125

0.250

0.500

|

|

Diaform |

SF 6632

SF 6633

SF 6672

SF 6673 |

3/8 x 2. ½

3/8 x 3

7/16 x 2. ½

7/16 x 3

|

|

| SHAPING TOOLS |

| TYPE |

CAT NO. |

DIMENSIONS |

Copying |

Fortuna |

|

Copying |

Schaudt |

|

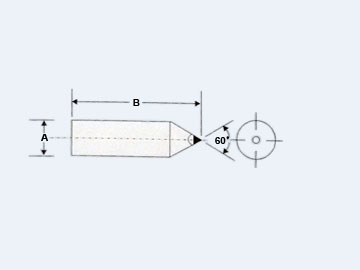

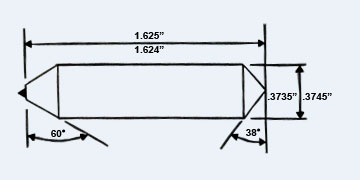

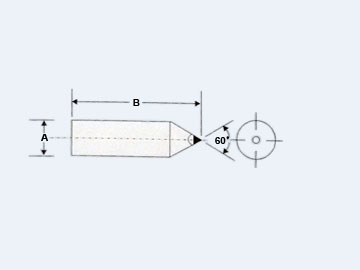

60° Lapped Dressing Tool |

Diamonds are ground and lapped to precise amgles. Tolerance: Centerset to TIR ± .002 Specify ∅ A & B |

|

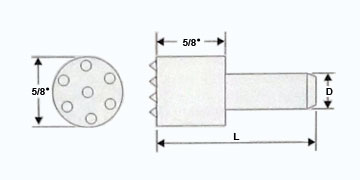

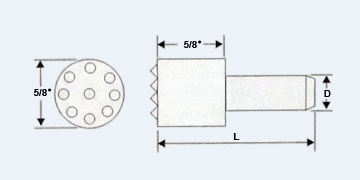

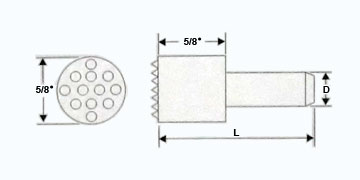

9. Cluster Dressers

| CLUSTER DRESSERS |

| SIZE |

CAT WT. |

DIMENSIONS |

5/D |

0.75 |

|

7/D |

1.05 |

|

9/D |

1.00 |

|

12/D |

1.00 |

|

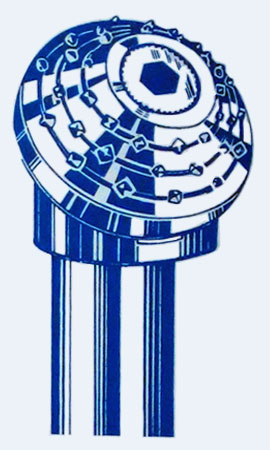

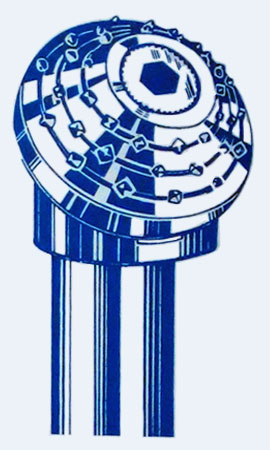

10. Multipoint Indexable Crown

A Multipoint Diamond Dressaer in which sharp natural diamonds are set in a circular crown at right angle to the operating plane. As soon as the diamonds on the indexed position are completely used up, the crown can be re-indexed on the shank for new points. Shanks for the crown are made to customer's specifications.

Applications:

• All types of large wheels where fine truing is considered important.

• Specially recommended for cylindrical grinders.

Advantages:

• The diamonds can be completely used up and resetting is redundant.

• Since two or more diamonds come in contact with the wheel the work load on the diamonds is divided and the diamonds last longer.

• A large area of the wheel is dressed more efficiently in a relatively shorter time than a single point.

• As several points are in use simultaneously the feed may be safely increased.

• Finer finish is obtained on the wheel due to the crystal shape of the diamonds employed.

• Can be used for side dressing.

Sizes:

• MIC-24 with 24 diamonds for wheel size up to 600 mm diameter wheel.

• MIC-36 with 36 diamonds for wheel size above 600 mm diameter wheel.

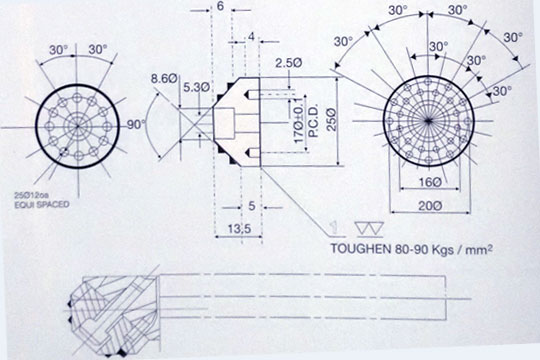

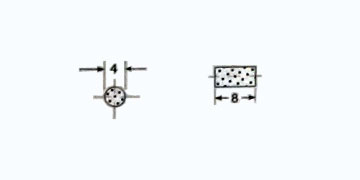

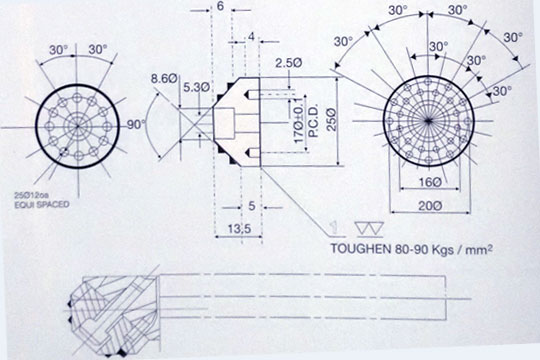

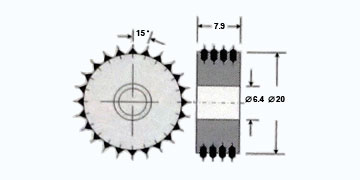

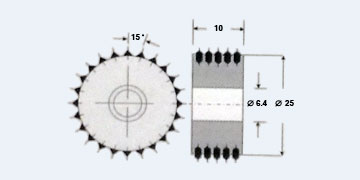

11. Multipoint Disc

Multipoint Disc dressers are normally used insmall grinding wheels on internal grinding machines. The diamonds are set evenly in rows across the face of the disc. First class needle shape diamonds are used, set in a special sintered bonds. Multipoint disc dresser are except that, alter each row of diamonds has been used, new points can be put into operation simply by rotating the disc slightly.

An ample supply of coolant and depth of the cut of 0.02 - 0.03 mm max are prerequisite for long tool life. Multipoint diac dressers can be used at any angle and therefore in any application.

To optimise the life of multipoint diac type dresser, we recommend that the complete disc be turned 180 from time to time to utilise the self sharpening effect produced by wear.

| MULTIPOINT DISC |

| CAT. NO. |

CARAT NO. |

DIMENSIONS |

HOLDER TYPE |

RECOMMENDATIONS |

MD 20 |

2.00 |

|

|

FOR DRESSING OF GRINDING WHEEL WITH STRAIGHT WORKING FACES |

MD 20 |

3.00 |

|

|

FOR DRESSING OF GRINDING WHEEL WITH STRAIGHT WORKING FACES |

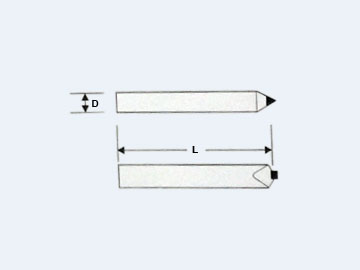

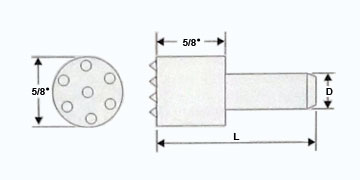

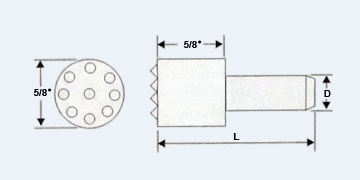

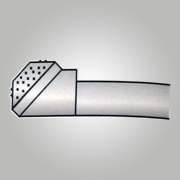

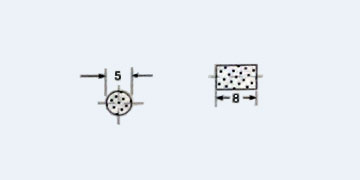

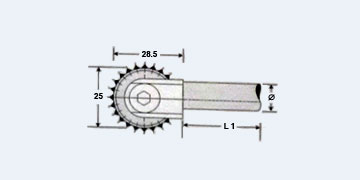

12. Diamond Grit Impregnated Dressers

Diamond grit impregnated dressers have been developed from multi-point dressers. In contrast to the latter they are manufactured from diamond grit rather than a large number of small natural diamonds. The advantages of the diamond impregnated dresser lie in its exceptional sharpness, which results from sharp edges and points of the diamond grit.

Diamond grit impregnated dressers are ideally suited to the following applications, dressing resin, vitreous and rubber bond, fine grit and even "grit free" grinding wheels, as well as boron carbide grinding wheels, dressing single profile threaded and V-profile grinding wheels, for general dressing operations on centreless, cylindrical and surface grinding machines.

Diamond grit impregnated dressers are more economical because of their low initial cost and their resistance to shock and impact which prevents shattering.

Dressing times are reduced as higher feed rates can be used. There is an unlimited number of sharp pull-out-free cutting edges contained in the crushed diamond grit.

Diamond grit impregnated dressers demand greater care in selecting the correct dresser for a given application. The bond and diamond grit size used are both variable according to the type of grinding wheels to be dressed. The size of the diamond grit particles should be matched to the grit of the grinding wheel.

Instructions for Use:

Normal dressing speeds are used. A plentiful supply of coolant should be provided both before and during dressing to prolong dresser life. The diamond grit impregnated dutting face of the dresser should be set at an angle of 90° to the grinding wheel to be dressed, so that all the cutting edges of the diamonds grit are able to make contact with the wheel face.

The feed rates used may be double of those used with single-point diamond dressers.

The depth of cut should be as follows:

Finishing - Appx. 0.01 mm

Rough Grinding - Appx. 0.02 mm

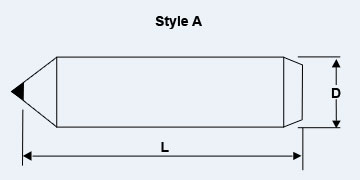

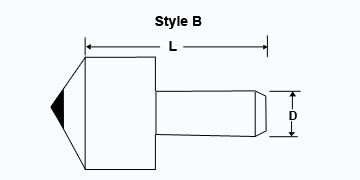

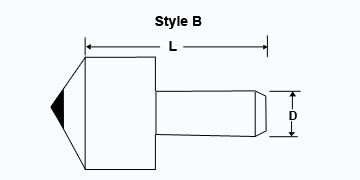

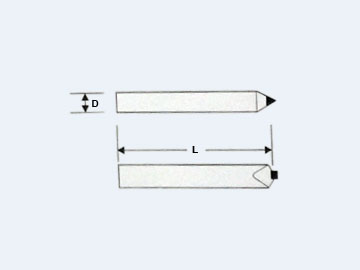

Note: While ordering please specify 'D' & 'L' diamentions & bond.

Long Life: Load is divided on many diamond particles in tough durable matrix.

No Reseting: In DGI Diamond Particles are totally consumed. The result is reduction in inventory.

| DIAMOND GRIT IMPREGNATED DRESSERS |

| CAT. NO. |

DIAMOND SECTION |

DIAMOND SIZE IN MICRONS |

BOND |

TDC-4 |

|

500 |

J |

TDC-5 |

|

500 |

J |

"The Solar Diamond Company which Manufactures the Widest Range of Diamond Tools, is one of the Suppliers in the World"

An engineering enterprise

An engineering enterprise